XINLIN MOULD YOUR HPDC TOOLING EXPERTSINCE 1991

Ningbo Xinlin Mould Technology Co., Ltd.

- SOLUTIONS

- …

- SOLUTIONS

XINLIN MOULD YOUR HPDC TOOLING EXPERTSINCE 1991

Ningbo Xinlin Mould Technology Co., Ltd.

- SOLUTIONS

- …

- SOLUTIONS

- SINCE 1991 -

YOUR HPDC TOOLING EXPERT

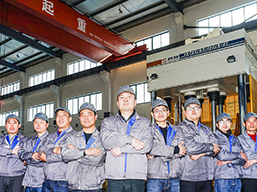

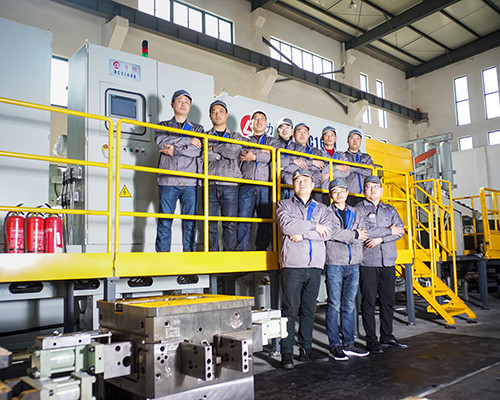

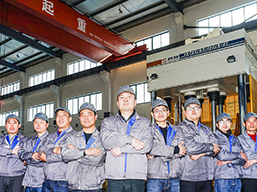

An outstanding and stable team, 30 years of experience, all to achieve:

Continuous Improvement, Sustainable Management.

ABOUT XINLIN

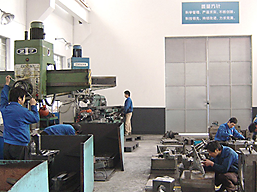

FACILITY

Two factories, 120 employeesNingbo XINLIN MOULD Technology Co., Ltd. (Previously Ningbo Beilun Xinlin Electro-Mechanical Mould Co., Ltd.) is located at the world famous harbour - Beilun Harbour. The city is also known as the "Hometown of China's Die-Casting Mould" with more than 70% of the country's HPDC tool makers concentrated in this small city. Xinlin has two plans, both manufactures HPSC tools and corresponding trimming tools. The two plants

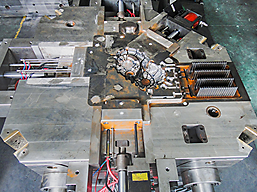

CAPABILITY

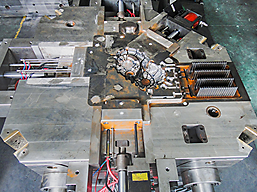

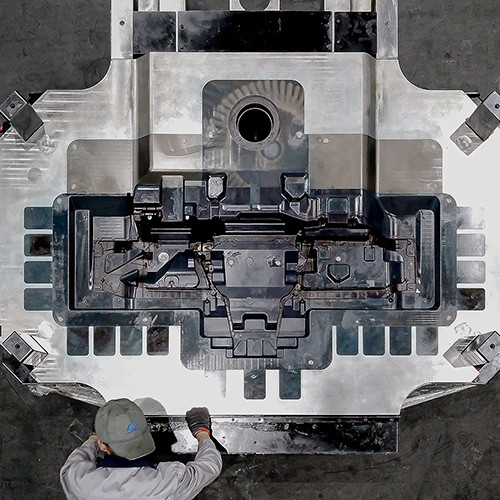

HPDC Tools up to 6,000 TonThe company was officially registered in 2003 and passed the SGS ISO9001:2000 in the same year. Currently, Xinlin has over 130 employees, including 30 engineers. The company is capable of producing aluminium and magnesium HPDC tools corresponding to 12,000 ton die casting machines, as well as large scale trimming tools up to 4m*5m. The annual production capacity goes beyond 250 sets.

PRODUCT

30% Exported overseasMore than 80% of our product is automotive industry related. We already established business relationships with Georg Fischer, Magna, Nemak, BorgWarner, Shiloh, ZF, Valeo, Wabco, TRW, Tesla, General Motors, Aisin, Sanden, Nidec, and many more global cooperations. Based on that, 30% of our sales revenue comes from overseas. Xinlin export tools to East Europe, France, Italy, United States, South-East Asia and South America. Our Service network covers Europe, the United States and South-East Asia.

XINLIN HISTORY

From a five man team to an industry leading company

1991

Fenglin Le and five of his apprentice rented a 32-square-meter workshop and started a company making plastic home switches.

2000

Le and his team purchased a 800-square-meter workshop in the Qingshan County, this is the very beginning of Xinlin Mould.

2003

Ningbo Beilun Xinlin Electro-Mechanical Mould Co., Ltd. was officially registered. The company was one of the very first company which passed SGS ISO9001:2000 certification at that time.

2005

Xinlin started tooling for oversea customers and making trimming tools. At the same time high pressure die-casting tools were becoming the main business for this company.

2009

The company moved to Chunxiao Industry Park, the new plant has a higher capacity and work space of 3,500 square meters.

2010

Xinlin successfully transformed its main business from home appliance/electric tools to automotive industry HPDC tooling.

2013

During its 10th anniversary, the company moved again to a new plant in Chunxiao, with an upgraded plant of 13,320 square meters. This plant is currently Xinlin South Beilun plant (Plant no. 1).

2014

Xinlin West Beilun Plant (Plant no. 2) was built in Lingfeng Mould Park - A government organized industry cluster for outstanding PDC/plastic tool manufactures. The new plant has production area of 9,500 quare meters.

2020

Responding to the market needs, Xinlin purchased a series of large size production/quality/assembly & testing facilities. The new arrangement is fully capable of manufacturing tools over 6,000 tons.

2021

Xinlin setup a secial R&D team dedicated for vehicle structural parts, designed for fast response, parallel analysing, co-development, material research and many other key characterestics of the heavy tonnage HPDC tools. This catalysed a rapid expanding in the corresponding market share.

2023

Third Factory (Anhui Xinlin Precision Mould Co., Ltd.) is under custruction, plan to be the largest super-heavy duty HPDC tool assembly & service center in inner lands of China

Since then, we are looking forward to “cast” another legend with you...

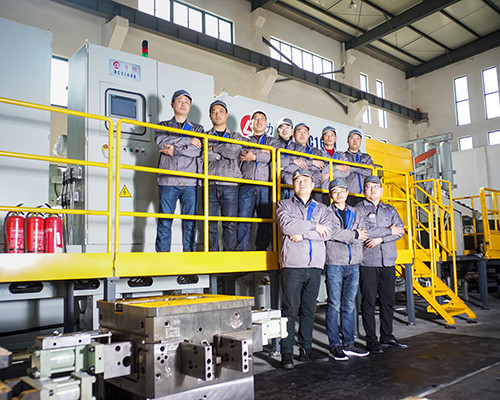

XINLIN TEAM

ENGINEERING DEPT.

Xinlin's engineering team is divided to two departments, separately responsible for product research/design and tool project management. This team is also capable of co-development with customers, and providing solutions for possible mass production.

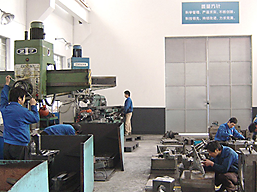

PRODUCTION DEPT.

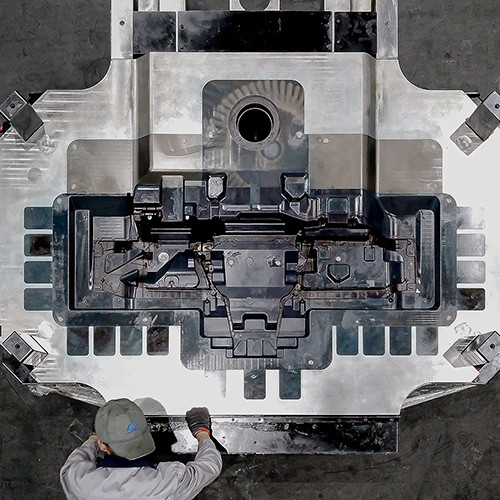

Xinlin developed its own ERP/MES system in 2020, according to actual production scene. Using not only the finest machineries but also the most suitable quality/management tools, our production team can be productive, yet remains stable and precise as well.

QUALITY DEPT.

During the production, we insert IQC/PQC process in every key point to ensure that we can find any tool failure as early as possible. With a complete collection of quality facilities we can also guarantee the quality of the tool trial.

ASSEMBLY TEAMS

Xinlin has 8 assembly teams, one backup team and one tool trial team, all together working in its 200-ton heavy duty tool assembly room. Every assembly team leader was certified with over 10 years experience of benchwork.

XINLIN MOTTO

Continuous Improvement, Sustainable Management.

Liability

Building long-lasting, stable business relationships with customers, suppliers, and employees.

Stability

Untilizing 30 years of tool production experience and digitalized system to make repetable and stable moulds.

Creativity

During the communication, Xinlin dares to insist on resonable opnions, continuously evolve with customers.

Competivity

Xinlin's goal is not only the quality of the product and service. We also strive to optimize cost and competivity.

Plant #1

XINLIN MOULD

27 Guanhai Rd.,

Chunxiao Ind. Park,

Ningbo China 315800

Tel:(+86)0574-86140263

Plant #2

JINLIN PREMAC

37 Guantanghe Rd.,

Beilun Mould Park,

Ningbo China 315800

Tel:0574-86133088

Copyright © 2021 by Ningbo Beilun Xinlin Electro-Mechanical Mould Co., Ltd.