XINLIN MOULD YOUR HPDC TOOLING EXPERTSINCE 1991

Ningbo Xinlin Mould Technology Co., Ltd.

- SOLUTIONS

- …

- SOLUTIONS

XINLIN MOULD YOUR HPDC TOOLING EXPERTSINCE 1991

Ningbo Xinlin Mould Technology Co., Ltd.

- SOLUTIONS

- …

- SOLUTIONS

GLOBAL COOPERATION

Xinlin has always been willingly cooperative with customers all over the world.

By achieving higher values for our customers, we continuously evolve at the same time.THE "HOMETOWN OF HPDC TOOLING"

Located in the city of Ningbo, China's "Hometown of HPDC Tooling"

Over 1,700 supply resources constantly ready for the HPDC Tooling Industry.

Lower cost and stable supply, where compatibility makes competitivity.

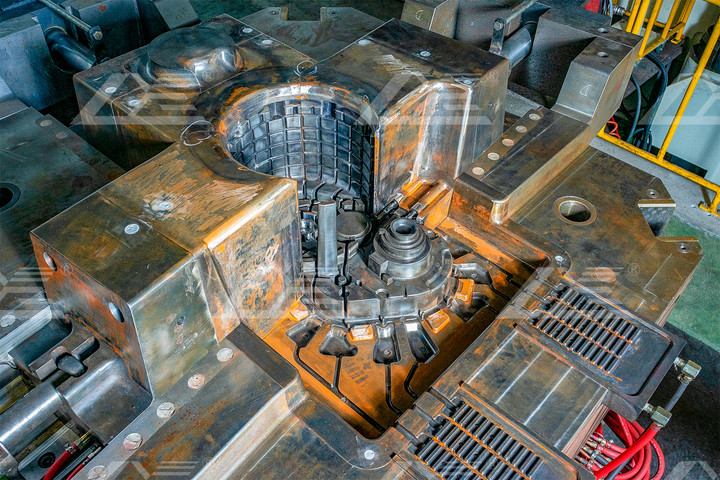

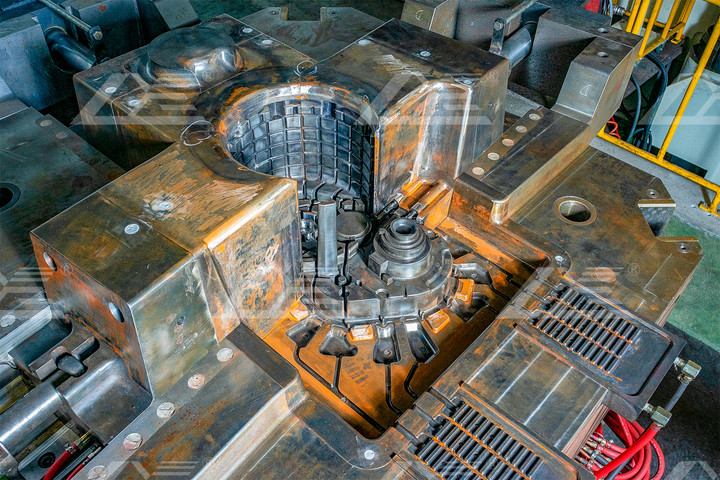

ORIGINAL LOTAS SOLUTION

Dedicated and highly integrated tool testing center with up to 2500-ton die casting machines,

early-stage confidence of tool & casting qualities, even before the tool shipped overseas.

LARGE SCALE

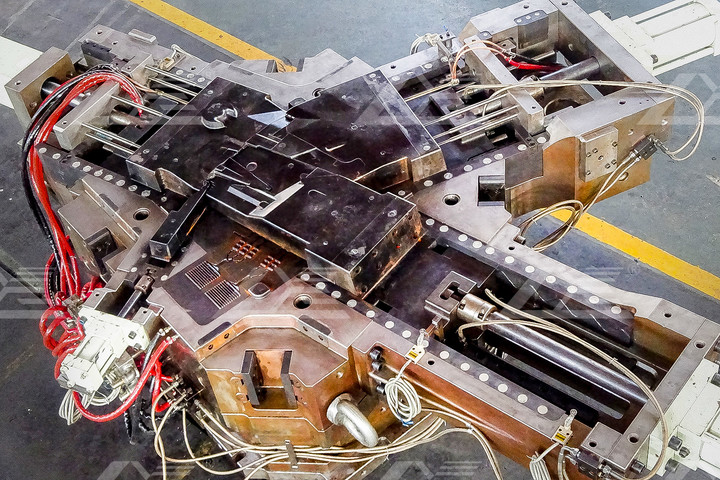

Industry-Leading 200 Ton Assembly Room

200 Ton Bridge Crane

1000 Ton Spotting Machine

100% Imported Fine Machining Equipments, Maximium capacity at Max 4m*5m

LIGHT WEIGHT

10 Years of Structure Part Tooling Experience

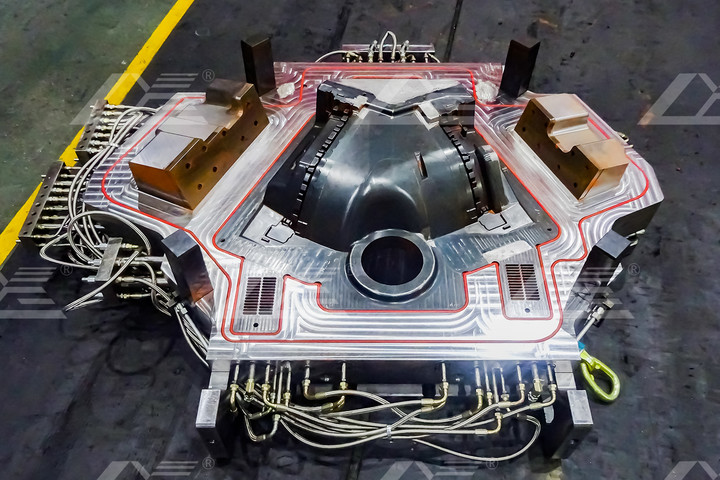

50mBar High Vacuum Tooling

Squeeze, SSM and Magnesium High Pressure Casting Solutions

ONE STOP

Original LOTS (Local Off-Tool Sampling) Solution

Highly Integrated Industrial Tool Testing Center

X-Ray Inspection, Vacuum Pump, HP Cooling Machine, Tool temperature control, etc.

A BRIEF INTRODUCTION

A Tooling Legend

Since 1991

Established in 1991, Xinlin has over 30 years of experience manufacturing tools.

With 12 years of flow simulation experience and almost 10 years of structural part tooling experience, we make sure that every HPDC tool we make will be a work of art.

130 Employees, Two Teams and

Differentiated Marketing

While ensuring the quality of the tool, Xinlin established two different production teams to reasonably control the manufacturing cost of the tools.

We can make sure that however the budget is, we can always find a way to maximize your competitivity.Continuous Improvement,

Sustainable Management.

Since 2016, Xinlin set an annual investment goal of over 2,000,000 USD in manufacturing and quality capabilities. Over 10% of our sales revenue turns into research and development to keep up technological advantage.

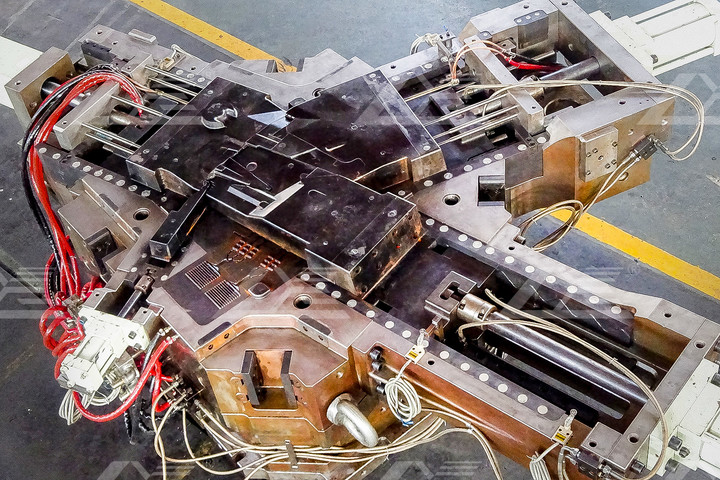

Now we can individually design, simulate and manufacture HPDC tools up to 12,000 tons.Original LOTS Solution,

Helping Globalization

During the COVID-19 period, Xinlin developed the original LOTS solution, localizing the on-tool-sampling stage of the casting within the tooling plant.

By simulating an on-to-one production scene at your factory, we can promise the quality of the casting even when you are far away overseas.

CERTIFICATION

OUR FACTORIES

Plant #1

Ningbo Xinlin Mould Technology Co.

Monthly production capacity: over 10 sets (>2500T)

over 4 sets (>4400T)

Vehicle Structural part

Electrical Vehicle Powertrain

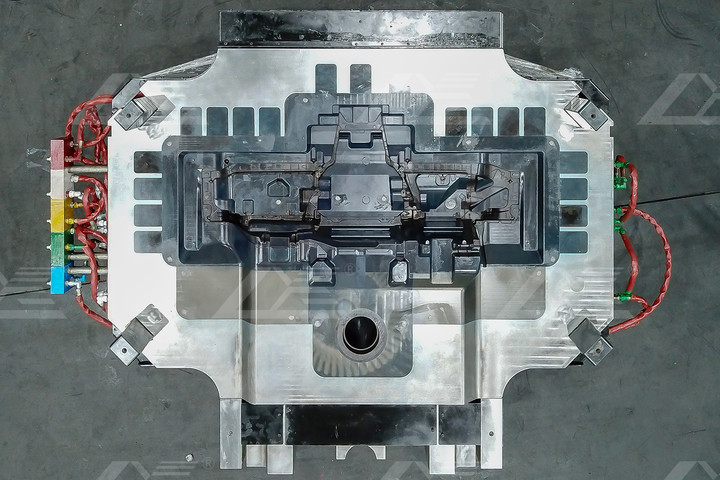

Electrical Vehicle Battery Compartment

Vehicle Powertrain System

Vehicle Transmission System

Vehicle Steering System

5G Communication

Large Size Die-Casting Trimming Tool

Plant #2

Ningbo Jinlin Precision Machinery Co.

Monthly production capacity: over 15 sets (<2500T)

Die-Casting Trimming Tool

Vehicle Transmission System

Vehicle Steering System

Vehicle Chasis & Mounting System

Vehicle Pumps & Brackets

Universal Machine Parts

★ Jaguar - Land Rover ★

Magnesium Center Console Bracket

Optimal Thermal Balance

No-Exhaust-Block Design

Enhanced Tooling Structure

★ Audi AG ★

Magnesium Armrest Bracket

Optimal Deformation

High Production Pace

Enhanced Mechanical Design

★ Audi AG ★

EV Battery Case Supporter Bracket

T7 Heat Treatment

Asymmetrical Design

50 mBar High Vacuum Design

Multiple Squeeze Pins

★ Borg Warner ★

3-in-1 EV Motor

High Qualification Rate

Optimal Thermal Balance

Enhanced Tooling Structure

BUSINESS PARTNERS

Plant #1

XINLIN MOULD

27 Guanhai Rd.,

Chunxiao Ind. Park,

Ningbo China 315800

Tel:(+86)0574-86140263

Plant #2

JINLIN PREMAC

37 Guantanghe Rd.,

Beilun Mould Park,

Ningbo China 315800

Tel:0574-86133088

Copyright © 2021 by Ningbo Beilun Xinlin Electro-Mechanical Mould Co., Ltd.